Brothers Satisfy Woodworking Passion with Portable Sawmill | Timbery

- By Timbery

- •

- 25 Jan, 2017

- •

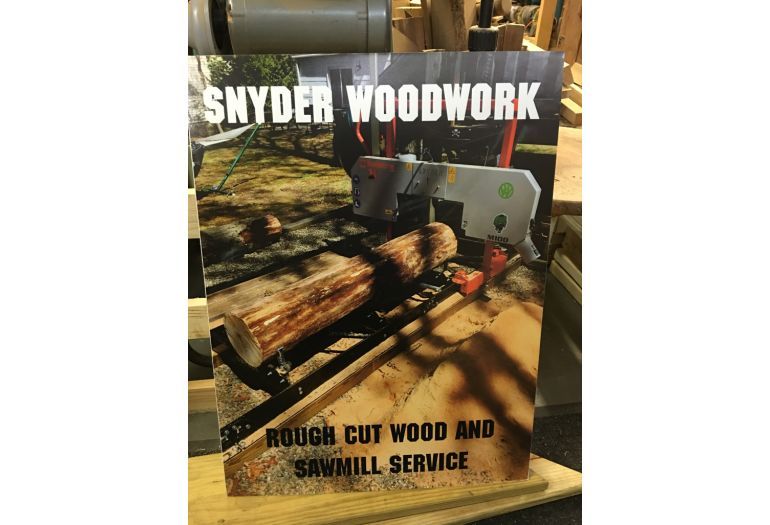

Twin brothers Bob and Ken Snyder have been passionate about woodworking throughout their entire lives. Beginning the craft at a young age, the Snyder’s particularly enjoy the creative process in turning lumber into toys, furniture, crafts, and other products they make to sell, give away, or keep for the enjoyment of themselves and their families. With their expertise in crafting a wide variety of toys including trains, 3D puzzles, and space crafts, it is fitting that the New Jersey natives converted an outdoor playground structure to house the Timbery M100 portable band sawmill they use to mill their own lumber for their woodworking projects. Likening the playground set up to a different kind of man cave, Bob says, “It’s like an outdoors man compound, friends come over to watch us saw logs and they end up enjoying our mill as much as we do!”

Bob and Ken began working with wood more than 40 years ago, responding to the influences of their father, Richard. “Dad always said that hard work is the best thing for you,” Bob says. “We were selling light bulbs at seven [years old] and using our dad’s basement workshop to make toys to sell when we were twelve.” According to Bob, their grandfather Earle also had a formative influence on the two men’s lives. Earle was a toy maker himself so many of the toys the boys made were based on patterns their grandfather had developed and much of what the boys learned about crafting wood and designing new wood products came under Earle’s mentorship. As the two learned more they began to expand their efforts, developing their own designs and making more elaborate toys.

Bob and Ken began working with wood more than 40 years ago, responding to the influences of their father, Richard. “Dad always said that hard work is the best thing for you,” Bob says. “We were selling light bulbs at seven [years old] and using our dad’s basement workshop to make toys to sell when we were twelve.” According to Bob, their grandfather Earle also had a formative influence on the two men’s lives. Earle was a toy maker himself so many of the toys the boys made were based on patterns their grandfather had developed and much of what the boys learned about crafting wood and designing new wood products came under Earle’s mentorship. As the two learned more they began to expand their efforts, developing their own designs and making more elaborate toys.

One of the problems the young men ran up against was the high cost of lumber, costs that seemed to steadily increase to the point where it was difficult to sell a product in order to produce a profit. A partial solution came from urban sourced trees in that homeowners would call their father to remove a tree that either needed to be taken down or had fallen down. “We’d load up in a Pontiac station wagon and head out to get the wood,” Bob remembers. “Some of the logs would be taken to a nearby sawmill and cut into lumber with the rest going into firewood. The lumber was stored in our attic until it was dry enough to use, approximately one year per one inch of thickness. I still have some of the lumber we cut back in those days waiting for just the right project.”

As the boys entered their late teens and early twenties, woodworking took a back seat as college, family, and careers suddenly came to focus in the twins lives, but Bob says the craft was never completely absent from their lives. Children’s cribs, high chairs, toys, and furniture for personal use and gifts took the place of wood projects made for sale as the twins took up their respective careers. Now at age 54, Bob and Ken have begun to build and market wood products driven by their lifelong woodworking passion and Bob’s purchase of a Timbery M100 personal sawmill. “My Timbery is the best $4,000 I ever spent,” he exclaims. “Sawmilling is like a natural therapy for me, it calms the mind but it’s exciting at the same time. The sawmill allows me to do things I couldn’t do before.”

As the boys entered their late teens and early twenties, woodworking took a back seat as college, family, and careers suddenly came to focus in the twins lives, but Bob says the craft was never completely absent from their lives. Children’s cribs, high chairs, toys, and furniture for personal use and gifts took the place of wood projects made for sale as the twins took up their respective careers. Now at age 54, Bob and Ken have begun to build and market wood products driven by their lifelong woodworking passion and Bob’s purchase of a Timbery M100 personal sawmill. “My Timbery is the best $4,000 I ever spent,” he exclaims. “Sawmilling is like a natural therapy for me, it calms the mind but it’s exciting at the same time. The sawmill allows me to do things I couldn’t do before.”

Timbery’s M100 sawmill is an entry-level machine used by woodworkers throughout the world who want to expand their creativity and material control in their projects. With the ability to saw logs up to 26” in diameter, the Timbery sawmill allows woodworkers to cut any species of logs into any dimension and grain pattern they want for project creation. By sawing their own custom lumber instead of buying materials at a big box store, the Snyder’s have saved money on lumber costs and increased their ability to work with any type of wood they desire.

The Snyder’s Timbery sawmill also plays into Bob’s plans to turn his hobby into a viable business in the future as retirement nears. “Right now I’m in the middle between a hobby and a business,” he says. “When I retire I intend to expand the business into about a six hour per day enterprise. Without the sawmill I’m not sure I could afford to sell my work due to the cost of lumber. Economically the sawmill opens up a whole new world of opportunity.”

In addition to expanded business potential, Bob says the Timbery sawmill allows him to explore his passion for wood to a much greater extent than would be possible without the mill. “To me sawmilling is not work,” he explains. “It’s a pleasure. People will call up and tell me they have a tree for me because they don’t want to see that tree just turned into firewood and they know I’ll use it well. People want their trees to come back to life. It’s exciting to them and it’s exciting to me when everything comes together and I’m able to make something for the very person who gave me the tree.”

From a personal standpoint Bob says one of the most important things his sawmill brings to the table is, “The freedom to become the artist you want to be. When you cut your own wood you’re not limited to anything, anywhere,” he explains. “You can discover the character of the wood as you cut to preserve irregularities in the wood and then use those irregularities in a creative way. While you’re cutting you can be thinking about what you might create with the board or block you’re cutting even though it might be a year or two of drying time until you can explore that vision.”

Bob points to blue oak as an example of how his mill allows him to explore his vision for a piece of wood. “Years ago someone drove a nail into an oak tree,” he says. “Over time that nail turns the wood blue. That wood is unique to me. With my mill I can cut to preserve the character of what some other people might consider to be a flaw and then turn the wood into a truly unusual work.”

To the Snyder brothers, woodworking is a passion with an intimate connection to the wood crafting heritage passed down to them by their father and their grandfather. Ownership of a sawmill has opened up a whole new world of opportunity to explore and expand on that heritage. “People say we sound like ambassadors for sawmilling,” he says, “And that’s true. Our sawmill allows us to realize our passion and vision for the wood we love to work with and we enjoy sharing that story with people.”

Timbery introduces Heicor Enterprises, LLC in Monmouth, Oregon as Timbery West - an authorized dealer of Timbery Portable Sawmills. Timbery offers a range of personal sawmills geared specifically for homesteads, farms, small woodlots, tree farms, as well as cabinet, custom woodworking, and specialty lumber shops.